According to Grand View Research’s market analysis report, the global warehouse management systems market is valued at USD 3,413.9 million in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 19.0% from 2023 to 2030.

Warehouse inventory management is crucial for supply chain and logistics, affecting business operations and success by effectively controlling and overseeing inventory within a distribution center. Coordinating tasks including receiving supplies, preserving stock quality, tracking, packaging, shipping, and refilling when stock reaches a certain level are all part of warehouse inventory management.

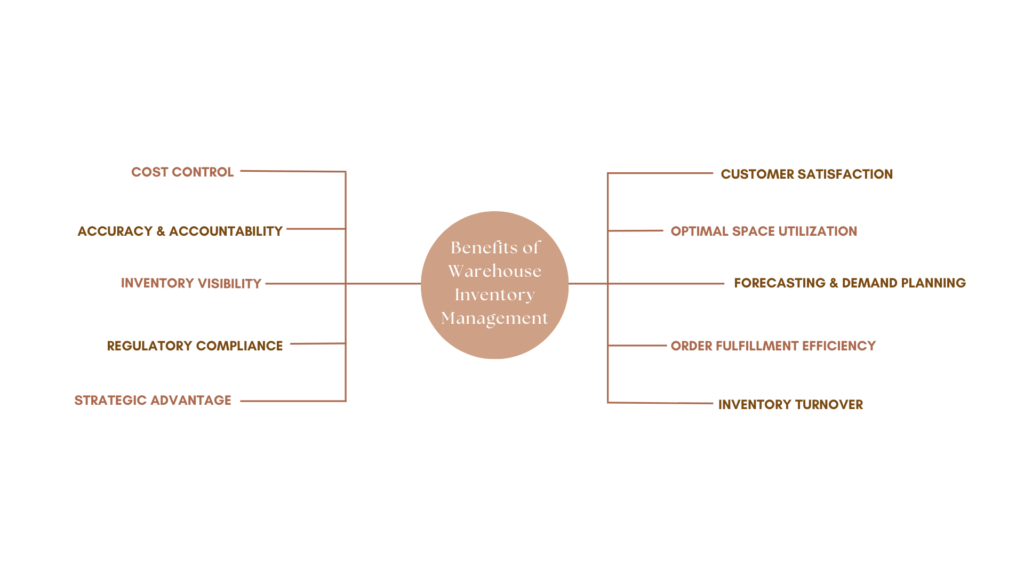

In this article, we will focus on the advantages of using warehouse inventory management and the best practices for doing so.

Overview:

Benefits of Warehouse inventory management

15 Best Practices for Warehouse Inventory Management

Effective warehouse inventory management helps businesses to optimize their operations, reduce costs, and enhance customer satisfaction. Here are the 15 best practices a business must follow to upscale the warehouse inventory management:

1.Utilize Inventory Management Software

Implement a robust inventory management system that can track stock levels, automate reorder points, and provide real-time visibility into inventory data. Many software options are available, such as WMS (Warehouse Management System) and ERP (Enterprise Resource Planning) systems.

2.Set Reorder Points

Determine reorder points for each item based on historical demand and lead times. Reorder when inventory levels reach these points to prevent stockouts and overstock situations.

3.FIFO (First-In-First-Out) or FEFO (First-Expired-First-Out)

For perishable or time-sensitive goods, implement FIFO or FEFO methods to ensure that older stock is used or sold before newer stock.

4.Regularly Audit and Inventory Cycle Count

Conduct regular physical inventory audits and cycle counts to verify the accuracy of your digital records. This helps identify discrepancies and prevent inventory shrinkage.

5.Implement Barcode or RFID Systems

Use barcode or RFID technology to streamline picking, packing, and tracking processes. These systems reduce errors and improve inventory accuracy.

6.Optimize Warehouse Layout

Organize your warehouse layout for efficiency, with popular items located closer to shipping areas. Use bin locations and clear signage to help employees quickly locate items.

7.Standardize Processes

Develop standardized procedures for receiving, storing, picking, and shipping inventory. Clearly communicate these processes to employees and ensure they are followed consistently.

8.Supplier Collaboration

Collaborate with suppliers to improve lead times, reduce order variability, and enhance communication. Building strong relationships can lead to more reliable supply chains

9.Demand Forecasting

Implement demand forecasting techniques to better predict inventory needs. This can reduce excess inventory and help with seasonal or demand fluctuations.

10.Safety Stock

Maintain a safety stock buffer for critical items to account for unexpected surges in demand or supply disruptions.

11.Training and Skill Development

Invest in training programs for warehouse staff to ensure they are proficient in handling inventory, using equipment, and following safety protocols.

12.Regular Performance Metrics and KPIs

Continuously monitor key performance indicators (KPIs) like inventory turnover rate, order fill rate, and accuracy of orders to identify areas for improvement.

13.Continuous Improvement

Encourage a culture of continuous improvement in your warehouse. Regularly review and refine your inventory management processes to adapt to changing business needs.

14.Cross-Functional Collaboration

Promote collaboration between warehouse, procurement, and sales teams to align inventory management with overall business objectives.

15.Sustainability Practices

Consider sustainable practices, such as reducing packaging waste and optimizing transportation, to minimize the environmental impact of your inventory management.

Conclusion

Investing in effective inventory management practices allows businesses to adapt to market changes, optimize resources, and achieve long-term success. Implementing these practices streamlines warehouse inventory processes, reduces costs, enhances customer service, and maintains competitiveness in their industries.

Propel Apps‘ innovative mobile solutions allow you to improve your warehouse inventory management. Request a demo to get a personalized guided tour of our one-of-a-kind digital solution platform.